PM1020H High-speed single-sheet inkjet printer

Category:

Product Introduction

With the development of variable data coding in China, the requirements for the accuracy, speed, and quality of inkjet equipment are getting higher and higher. Combining more than ten years of industry application experience and feedback from numerous customers, the PM series products are constantly being upgraded and improved. The PM1020H single-sheet high-speed inkjet printer is specially customized for high-end packaging coding such as cigarette packs and cosmetics.

Technical Parameters

*Normal operating speed depends on the inkjet system and paper quality.

Paper Feeding Unit

• Uses a higher-performance offset press feeder head, with a maximum paper feeding speed of 15000 sheets/hour, ensuring stable high-speed production and a long service life;

• The interval between sheets of paper can be adjusted according to user needs;

• Direct paper feeding without stopping the machine, enabling quick conversion of paper processing procedures, eliminating the need for manual paper alignment, and reducing labor intensity.

Positioning System

• Reinforced structure with positive and negative diagonal tensioning guides, for higher positioning accuracy, and equipped with auxiliary guides to ensure more stable and reliable paper running;

• Equipped with ultrasonic double-sheet detection.

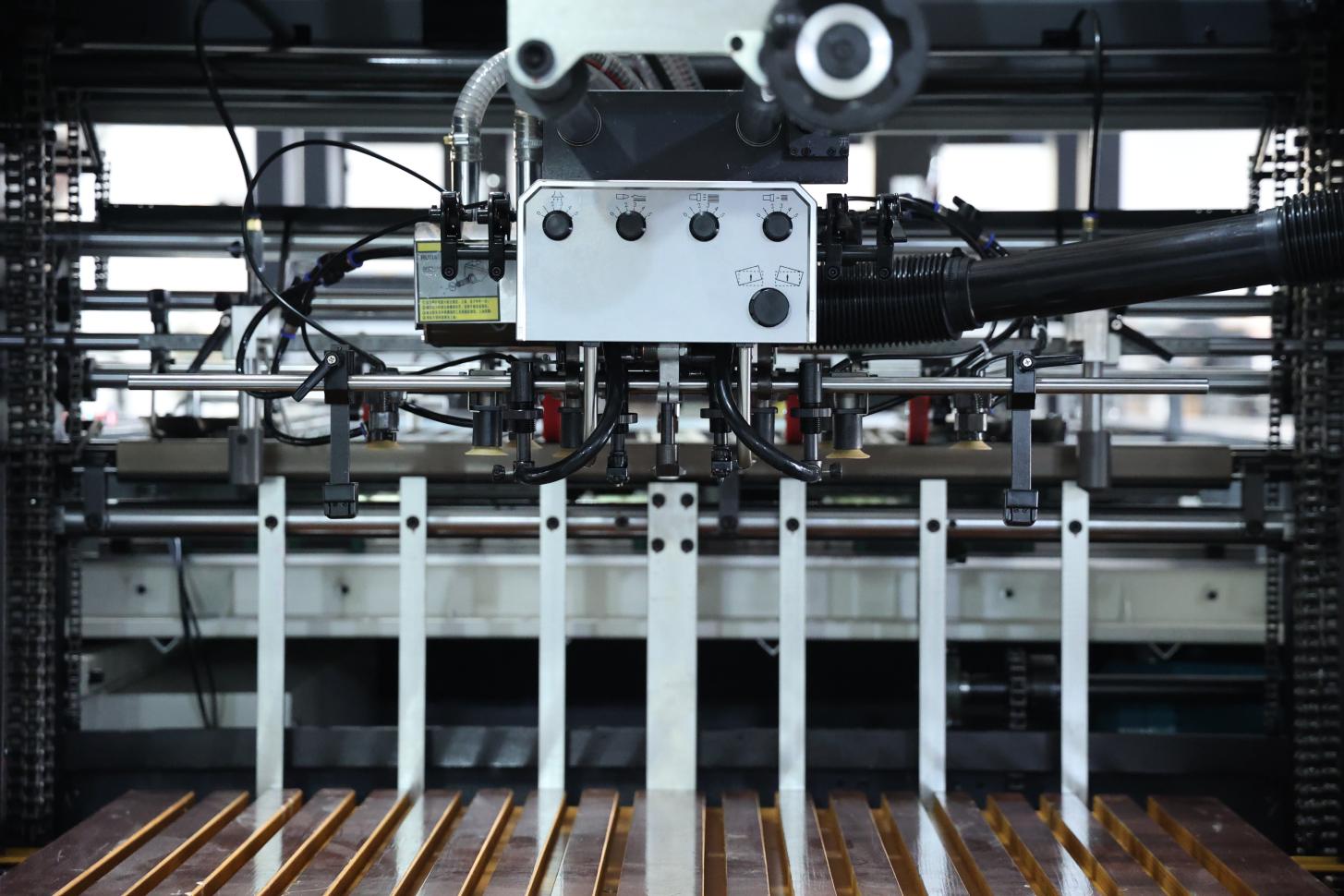

Inkjet Platform Unit

• Overall cast iron wall plate, 40mm thick, good stability, low vibration, stable high-speed operation;

• Overall suction chamber, with zoned suction control, ensuring flat paper adsorption.

• 3-meter adsorption space, compatible with the installation of high-speed inkjet and detection systems.

• Drawer-type fan design, split wall plate design, for easier maintenance.

LED UV Platform Unit

• Special UV-resistant wide-width belt, vacuum adsorption;

• Reserved space for online detection, allowing for more applications.

Paper Receiving Unit

• Fish scale stacking paper receiving;

• Vibration motor paper alignment device, for neat paper receiving;

• Equipped with a waste rejection device, working with online detection for automatic waste removal;

Keyword:

coding machine

Inkjet machine

Previous Page:

Next Page:

Related Products

Online Message

If you are interested in our products, please leave your email, and we will contact you as soon as possible. Thank you!